- Introduction

- Features

- System & Hardware requirements

- Installation

- Setup & Calibration

- Licensing

- FAQ

- OT-500 Bundle

Version: 20221019_V1-4-1

last update; 20th October 2022

Introduction #

OptiTUIO™ is a tool to calibrate optical LIDAR sensor devices. With OptiTUIO™ it is possible to use laser contour scanners like the Leuze ROD4plus, Hokuyo sensors, or the Sick LMS models for controlling any number of applications. OptiTUIO™ generates and detects unlimited touchpoints which then can be detected and processed by compatible applications and devices. OptiTUIO™ has 3 different output modes, TUIO, Mouse, and Windows Touch. That means that any application which understands TUIO, Mouse, or Windows Touch can get controlled with OptiTUIO™. With our solution, you literally transform any flat surface into a multitouch surface.

Features #

- Simplicity The software is very easy to use. The calibration process is finished after a few minutes. You can see what you are doing and the effect it has in realtime, so there is no need for time consuming switching between calibration and testing like in other solutions.

- Live preview You can see in realtime what you are doing. Our live preview shows you exactly where your sensor is placed and where your screen is placed. Fine-tuning is very easy to realize.

- Unlimited touch points We did not put any artificial limit on the number of simultaneous touch points.You can track as many as you want. The upper limit is a result of the angular resolution of the laser and the minimal object size that you set to detect.

- Many output methods Right now the software supports output to TUIO compatible devices over the network and to simulate Windows mouse and/or touch input to control a local Windows application. We also provide a separate application to perform gesture detection to control PowerPoint using swipes for example. Contact us if you need anything specific.

- Vendor independence Our software works with most of the common LIDAR sensors. This gives you the flexibility in choosing the device that fits best for your project and budget. Depending on which sensor you choose you can get up to 50 meters of detection radius with just one sensor. If there is a new sensor on the market we will try to implement it by request. See Section 3.3, “Supported LIDAR sensors” to find more.

- Multiple outputs Each output can be sent to one ore multiple different outputs. Giving you full flexibility in how to distribute them. You can also define multiple outputs to send the data of one device to many target machines, this is useful for cluster setups.

- Highly optimized detection algorithms We spent a long time building and analyzing statistics of the accuracy of the devices to optimize our filters to get the most accurate tracking possible. For each device we acquired millions of data points to get an accurate statistical analysis. This is why we are able to get a fully stable input without any jitter in the measurement. We took much care to keep the impact on latency minimal and you can tune the filter parameters yourself to get a different trade off between smoothness and latency.

- Multilingual User Interface To make it easier for any user to understand and use OptiTUIO. For now the following languages are available in the GUI (Graphical User Interface):

- English

- German

- Chinese

- French

- Arabic

- Portuguese

- Spanish

- Thai

We will translate the software into more languages if there is a need.

System & Hardware requirements #

Supported operating systems #

- Mac OS X 10.12 Sierra or newer (not supported for future releases – last release 1.2.3)

- Windows 7 or newer

- Ubuntu 16.04 Xenial Xerus or newer

- Debian 8 Jessie or newer

Hardware requirements #

- A recent x86 or x86-64 CPU supporting SSSE3

- Intel starting from Core 2 and Atom

- AMD starting from Bobcat APU

- At least 100 MiB of free HDD space

- At least 256 MiB of free RAM

- For the calibration software, an OpenGL 2.0 compatible graphics card is required

Supported LIDAR sensors #

- Hokuyo UST-10LX (OT-1000)

- Hokuyo UST-10LX H01 (OT-1500)

- Hokuyo UST-20LX

- Hokuyo UST-20LX H01 (OT-2000)

- Hokuyo UST-30LX (OT-3000)

- Hokuyo URG-04LX

- Hokuyo UTM-30LX

- Leuze ROD4 plus series

- Sick LMS 1xx series

- Sick LMS 5xx series

- Sick LMS 4000 series (High-Speed Sensor)

- KELI LS1027/H03-E (OT-800) (we only support sensors you bought from Interactive Asia Co. Ltd)

- LeiShen LS01B

- LeiShen N301

- LDROBOT LD06 (OT-500)

!! Don’t change the firmware unless instructed by us or the manufacturer of the device !!

| Sensor | Hokuyo | Hokuyo | Hokuyo | Hokuyo | Hokuyo | Hokuyo | Sick | Sick | Sick | Leuze |

| Bundle Name | OT-1000 | OT-1500 | OT-2000 | |||||||

| Model | UST-10LX | UST-10LX H01 | UST-20LX | UST-20LX H01 | URG-04LX UG04 | Hokuyo UTM-30LX | LMS 1xx | LMS 5xx | LMS 4000 | ROD4 plus |

| Accuracy | ±30mm | ±20mm | ±30mm | ±20mm | ±30mm | ±30mm | ±25mm | ±25mm | N.A. | N.A. |

| Measuring area | 270° | 270° | 270° | 270° | 240° | 270° | 270° | 190° | 70° | 190° |

| Angular resolution | 0.25° | 0.125° | 0.25° | 0.125° | 0.36° | 0.25° | 0.25°/0.5° | 0.166°/1° | 0.0833° | 0.36° |

| Scan rate | 40Hz | 40Hz | 40Hz | 40Hz | 10Hz | 40Hz | 25Hz/50Hz | 25Hz-100Hz | 600Hz | 25Hz/50Hz |

| Scan Range | 10m | 10m | 20m | 20m | 3m | 30m | 20m | 30m | 0.7m – 3m | 15m |

| Connection | Ethernet | Ethernet | Ethernet | Ethernet | USB | USB | Ethernet | Ethernet | Ethernet | Ethernet |

| Outdoor | No | No | No | No | No | No | Yes | Yes | N.A. | Yes |

| Multi Echo Filter | No | No | No | No | No | N.A. | Yes | Yes | N.A. | Yes |

| Ambient light | 15000lx | 15000lx | 15000lx | 15000lx | 10000lx | N.A. | 40000lx | 70000lx | 2000lx | Sunlight |

| Enclosure rating | IP65 | IP65 | IP65 | IP65 | none | N.A. | IP65/IP67 | IP65/IP67 | N.A. | IP65 |

| Sensor | KELI LS | LeiShen | Hokuyo | LD ROBOT LD06 | ||||||

| Bundle Name | OT-800 | OT-3000 | OT-500 | |||||||

| Model | LS2 | LS01B1 | UST-30LX | LD06 | ||||||

| Accuracy | ±20mm | ±20mm | ±20mm | ±30mm | ||||||

| Measuring area | 270° | 360° | 270° | 360° | ||||||

| Angular resolution | 0.33° | 0.25° | 0.25° | 1° | ||||||

| Scan rate | 28Hz | 10Hz | 40Hz | 10Hz | ||||||

| Scan Range | 8m – 10m | 5m | 30m | 0.02 – 12m | ||||||

| Connection | Ethernet | USB | Ethernet | USB | ||||||

| Outdoor | No | No | No | No | ||||||

| Multi Echo Filter | No | No | No | No | ||||||

| Ambient light | N.A. | N.A. | 15000lx | 30000lx | ||||||

| Enclosure rating | IP65 | N.A. | IP65 | IPX-4 | N.A. | N.A. | N.A. | N.A. | N.A. | N.A. |

Installation #

!! Don’t change the firmware unless instructed by us or the manufacturer of the device !!

Windows #

On a Windows machine, there is no need to install OptiTUIO™. You will get a zip archive that contains the folders explained below. Then you just need to start the application with a double click.

Make sure that you install the Visual C++ runtime. You can find the vcredist_x64.exe in the OptiTUIO™ bin32 or bin64 folder.If the Runtime is not installed OptiTUIO™ will not start. |

Folders #

After you download the latest OptiTUIO™ release you have to extract the archive first. In the extracted folder you can find the following folders:

- The bin32 folder holds the 32bit files.

- The bin64 folder holds the 64bit files.

- The docs folder holds software licensing information and the latest release notes in the CHANGES.html

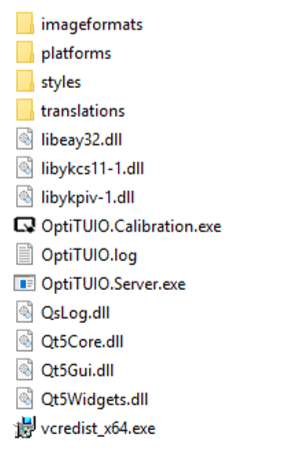

In the bin32 or bin64 folder you can find the following files:

In this folder you can find the main OptiTUIO applications and the Visual C++ runtime:

- OptiTUIO.Calibration.exe (the main calibration application)

- OptiTUIO.Server.exe (the runtime / server application)

- vcredist_x64.exe (Visual C++ runtime)

Find more info here how to [Autostart the server]

MacOS #

Will be updated soon.

Linux #

Will be updated soon.

Setup & Calibration #

This chapter describes the whole process of the calibration with the OptiTUIO.Calibration.exe including how to install the license.

Quick Start #

This is a short intro for a quick setup of OptiTUIO™:

- Connect the sensor to your machine and make sure that the machine can communicate with the sensor (Pingtest) or check the correct USB connection with the OT-500

- The OT-500 bundle uses the LDROBOT LD06 device

- The OT-800 bundle uses the KELI LS device

- The OT-1000/1500/2000 uses the Hokuyo URG device

- Start OptiTUIO™ and Add your sensor in the Devices Tab

- Click the Info button to get the serial number of your device. Send this serial number to info@interactiveasia.com to receive your purchased license.

- Start the sensor with the Start button under the Devices tab. If the sensor scans correctly you can see the blue scan area in the sensor view.

- Add your screen and setup the dimensions of the screen

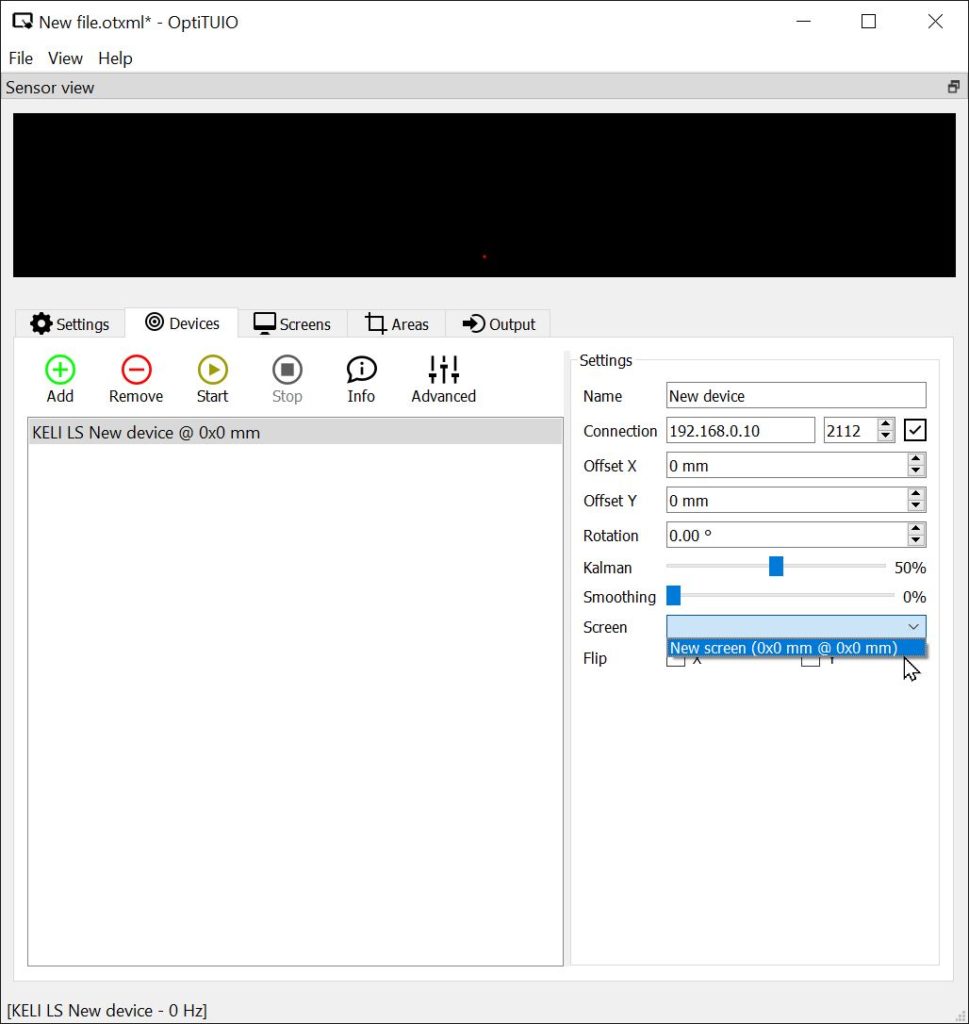

- Assign the screen to the sensor in the Devices tab und Screen in the Settings

- Add your desired output

- Now OptiTUIO™ is working and you should be able to get a touch feedback already depending on the output you defined.

Network Basics #

To make sure that the sensor and the computer that is running OptriTUIO can communicate you need to make sure that both devices (sensor and computer) are in the same network.

Please follow the steps in the link below

https://wiki.interactive-asia.com/index.php?title=Hardware_/_Networking

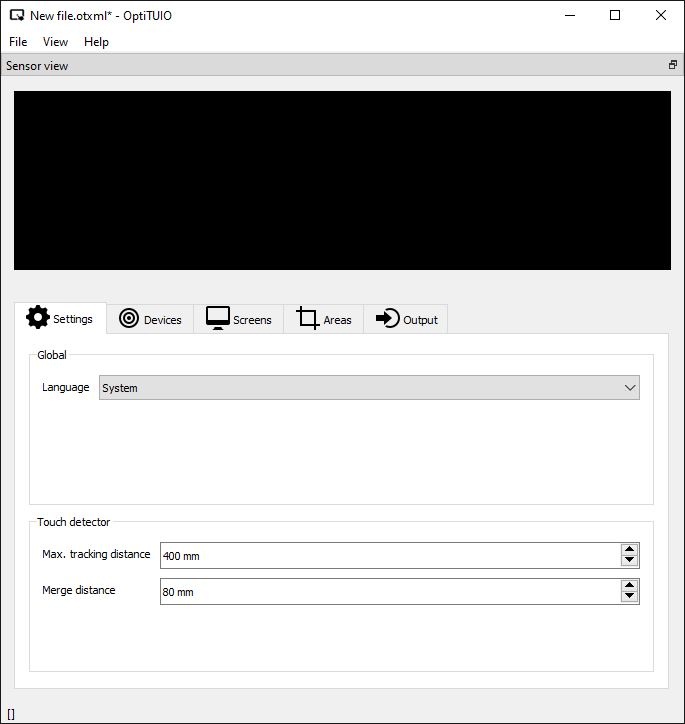

First Start #

Double-click the OptiTUIO.Calibration.exe

The Graphical User Interface of OptiTUIO™ will start

In the main menu you can find the typical menu entries:

- File – To load configuration files, save configuration files and exit the application

- View – To customize the preview window and open the Log window.

- Help – To install the license and view the license details.

- Language – Change the User Interface to your desired language

- Max. tracking distance – This value specifies from which distance to an existing touch point a new touch point is detected or if it is an existing one. Normal values are between 100mm – 400mm

- Merge distance – This value specifies the distance from which two touch points get merged together into one. Very helpful when applications are controlled with fingers on short distances, for example. Standard value is 40mm.

The GUI has the typical menu bar, the sensor view, and the tab area.

In the menu bar, you can load, save and create new calibrations.

You also can adjust the view and under the Help menu, you can install the license and get more information’s about OptiTUIO™ and the license.

In the sensor view, you will see the contour of the scanned area when the sensor is scanning. In the tabs area, you do the main calibration and adjustments.

In the bottom left corner, you will see the scan frequency of the running sensor.

| Check the hardware specifications and Operating System requirements if you have any trouble starting OptiTUIO. Find this in Chapter 3. |

Read out the serial number of your sensor #

To create your license we need to have the exact serial number of your sensor. You can read it out with OptiTUIO™. Click the Info button in the Devices tab. A popup will appear with your sensor’s unique serial number.

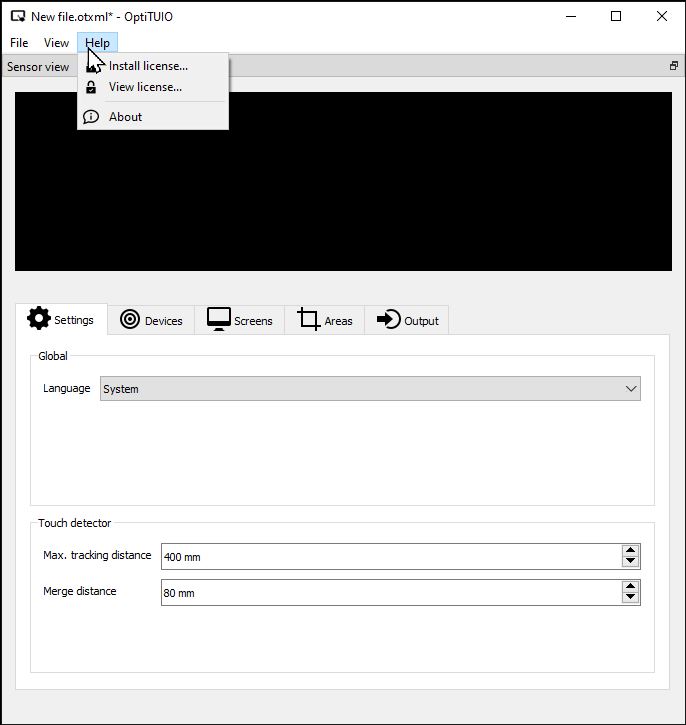

Install the license #

Until now (OptiTUIO™ Version 20201204_V1-2-5) our license system is based on a soft license. That means we will create a license file for you which you then have to assign in OptiTUIO™. The license file is bound to your sensor’s serial number. This means you can use the device license on any computer with the licensed sensor. If you have more than one sensor and also bought the license for all the sensors then we can create you a license file that contains all the licensed sensors. You can install the license file under the menu item Help -> Install license.

Additionally, we offer an online demo license that can work with any connected sensor. The requirement for this is that the machine which runs OptiTUIO™ is connected to the internet.

After you successfully installed the license you can check under Help -> View License for more details about your installed license.

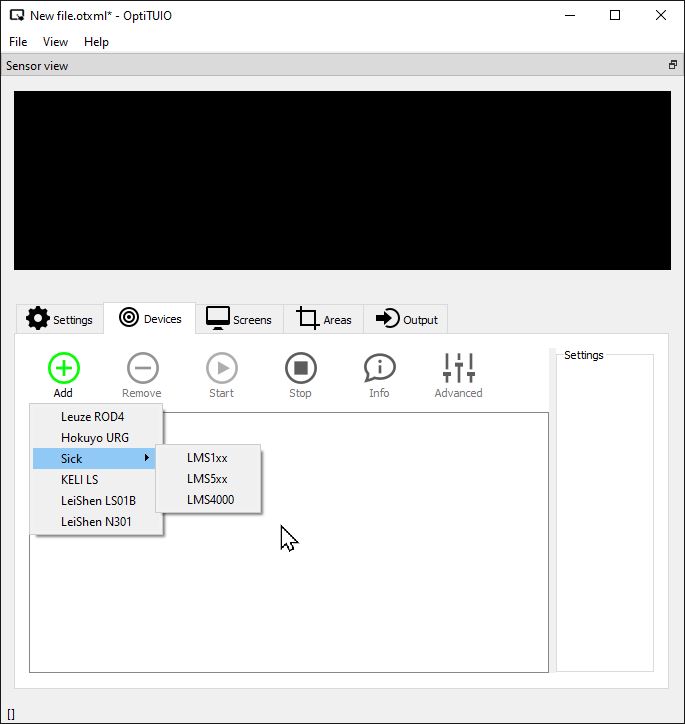

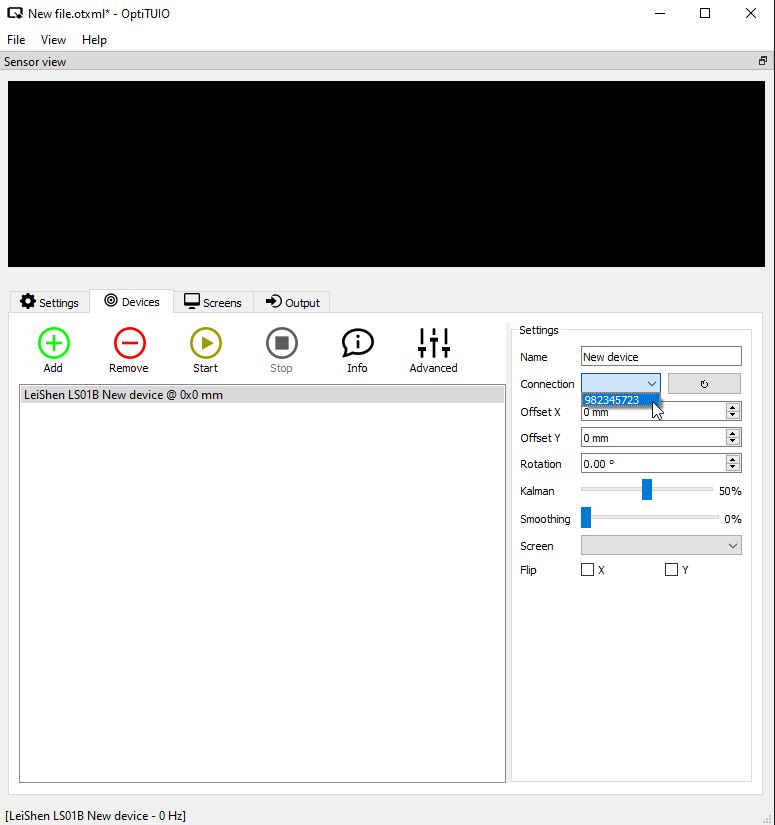

Add a sensor #

Add your sensor in the devices tab.

| The Hokuyo UST 10 LX(H01), Hokuyo UST 20LX(H01) and the Hokuyo URG04 can be added via the Hokuyo URG item. This item includes all the Hokuyo sensors. |

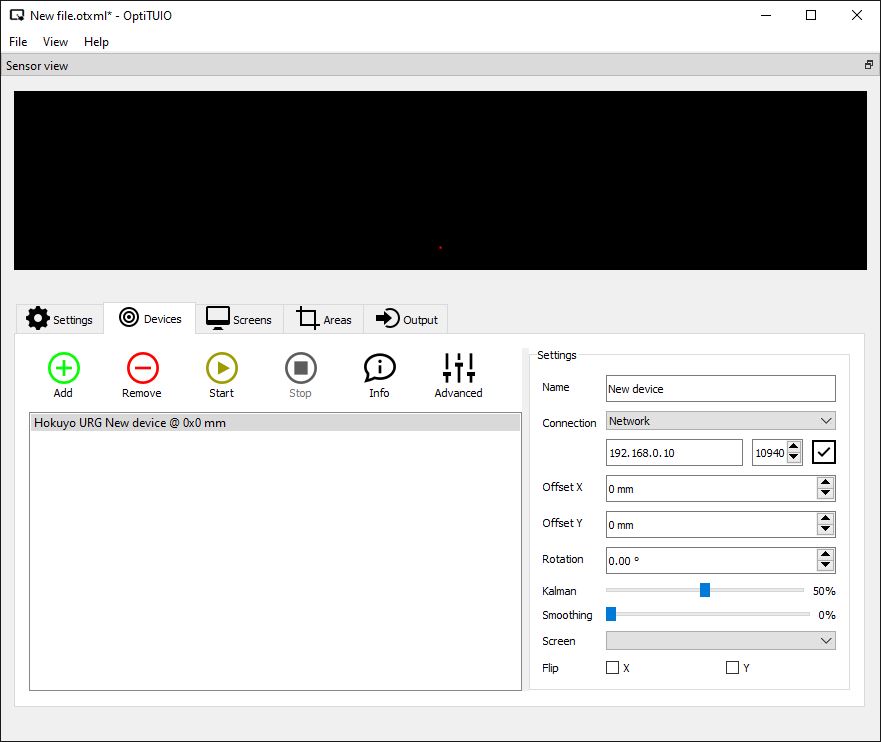

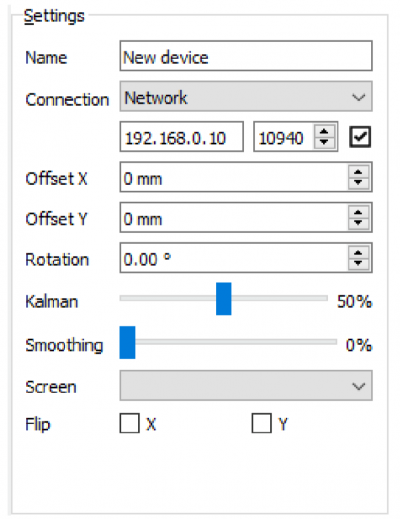

Settings of the sensor #

Here we describe the settings of a Hokuyo UST 10 LX sensor. The settings are very similar to other sensors.

Once you added a sensor in the Devices tab the icons above the sensor list will be activated and the properties of the sensor will get available on the right side under the settings area.

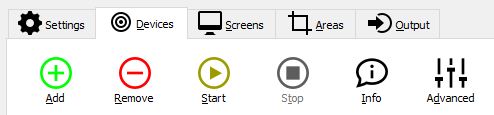

This is the control panel to add, remove, start and stop the sensor.

- Add – this button opens the available sensor list where you can choose your sensor

- Remove – this button removes the selected sensor

- Start – Starts the sensor and the sensor will start scanning. If the sensor is runnig you can see the blue scanning area in the sensor view window

- Stop – Stops a running sensor and the sensor will stop scanning

- Info – This button shows you the serial number of the connected sensor. This button just works if the sensor is not running and connected correctly.

- Advanced – opens a new window where you can access [Advanced Setting]

| If you connected a sensor you can read out the serial number of the connected sensor via the Info button |

On the right side you have access to the settings of the specific sensor:

- Name – Here you can give your device a name

- Connection – By default the connection is set to Network. If you use the Hokuyo URG04 with a USB connection then you have to change this value to serial

- Offset X – Offset the sensor in X direction (left / right)

- Offset Y – Offset the sensor in Y direction (up / down

- Rotation – Adjust the Z rotation if your sensor is offset in Z direction

- Kalman – Maximum deviation of the measured values to the actual distance. It is recommended to use the default values per device.

- Smoothing – This value will make the control smoother. But the higher the value is they more delay you will get.

- Screen – Here you have to assign the screen which you have created under the Screens tab.

- Flip x/y – Depending on the orientation of the sensor you can flip the values in X and Y

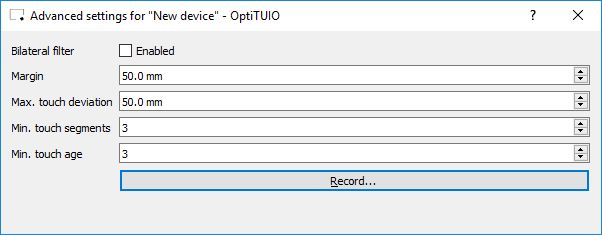

Advanced Settings #

If you change this setting OptiTUIO might not work anymore. For a normal setup, you don’t need to touch these settings.

In this tab, you have access to some advanced features.

| These values are just exposed for our developers and some special cases. They should not be changed for normal usage |

- Bilateral filter – For some special setups, especially when there are some error close to the sensor you can try to turn this option on. (default = off (unchecked))

- Margin – in some special cases you can adjust the margin that the touches are also recognized a bit outside of the actual touch area.

- Max. touch deviation – This is a very specific value and should not be changed!!!

- Min. touch segments – Defines how many rays have to recognize a object until its recognized as a touch point (default = 3)

- Min. touch age – The age of a touch point in frames before he gets sent to the output.

- Record button – Here you can record a file of the tracking process to send it to us for troubleshooting issues

Start the sensor #

- Make sure that your sensor is connected correctly. You have to make sure that the computer which is running OptiTUIO™ is in the same sub network like the sensor.

- The OT-1000 and the OT-800 using by default the IP address 192.168.0.10 (If you are using a second hand sensor make sure that you know the correct IP address of the sensor)

- Make sure that your computer is in the same network or change the IP address of the sensor to your desired IP address.

- If you are able to ping the sensor via ping 192.168.0.10 then OptiTUIO™ will be able to connect to the sensor too.

- You can ping the sensor if you open a cmd window in Windows

Windows Key + r. Then typecmdin the Run Window and press Enter. - In the command window type

ping 192.168.0.10or the correct IP address of your sensor. - If you get a positive feedback from the sensor OptiTUIO™ will be able to connect to the sensor.

- You can ping the sensor if you open a cmd window in Windows

- Select the sensor in the Devices tab and click Start in the control panel.

- Once the sensor is started you can see the blue scan area in the sensor view.

- In the bottom left corner of the GUI you can also see the scanning frequency of the sensor.

| Make sure that your network configurations are set up correctly. Find more info here Hardware / Networking |

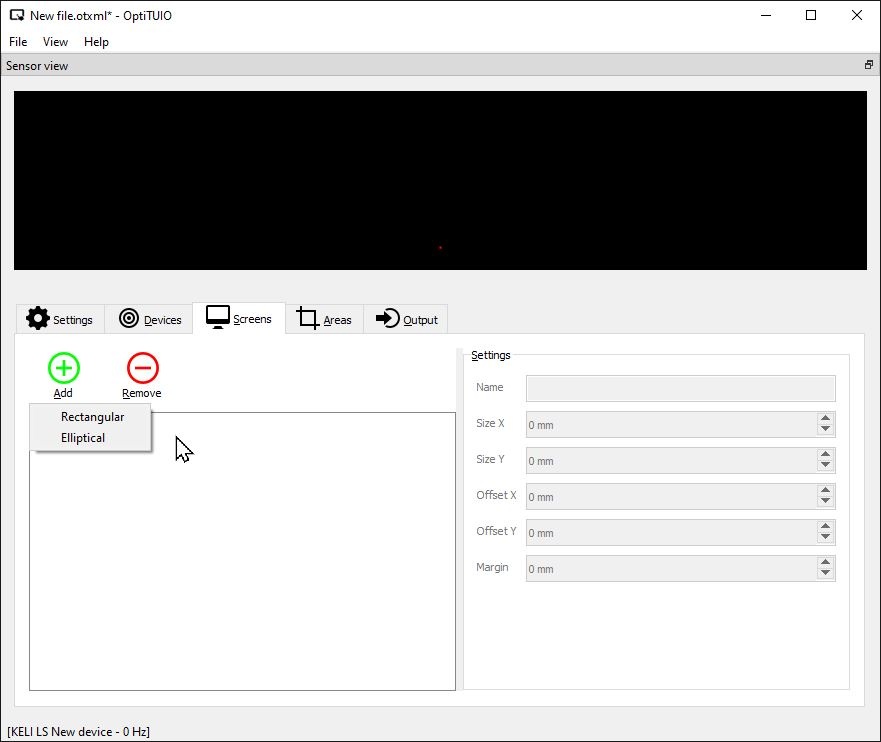

Setup the screen #

Click the Screens tab and then the Add button to add a new screen.

You can choose between a rectangular and a circular screen layout.

Then set up the Size X (width) and the Size Y (height) of the screen in millimeters.

And adjust the offset between the screen and the sensor. (You can do this also in the devices tab)

You can choose between a Rectangular and an Elliptical screen

- Name – Setup a name for your screen

- Size X – The width of the physical touch screen area in mm

- Size Y – The height of the physical touch screen area in mm

- Offset X – offset the screen left or right in relation to your device

- Offset Y – offset the screen up or down in relation to your device

Add the screen to your device #

!! This is an important step !!

After you created your screen, you have to go back to the Devices Tab and add your recently created screen to your device. After this step, OptiTUIO will show red and green dots for every recognized TouchPoint.

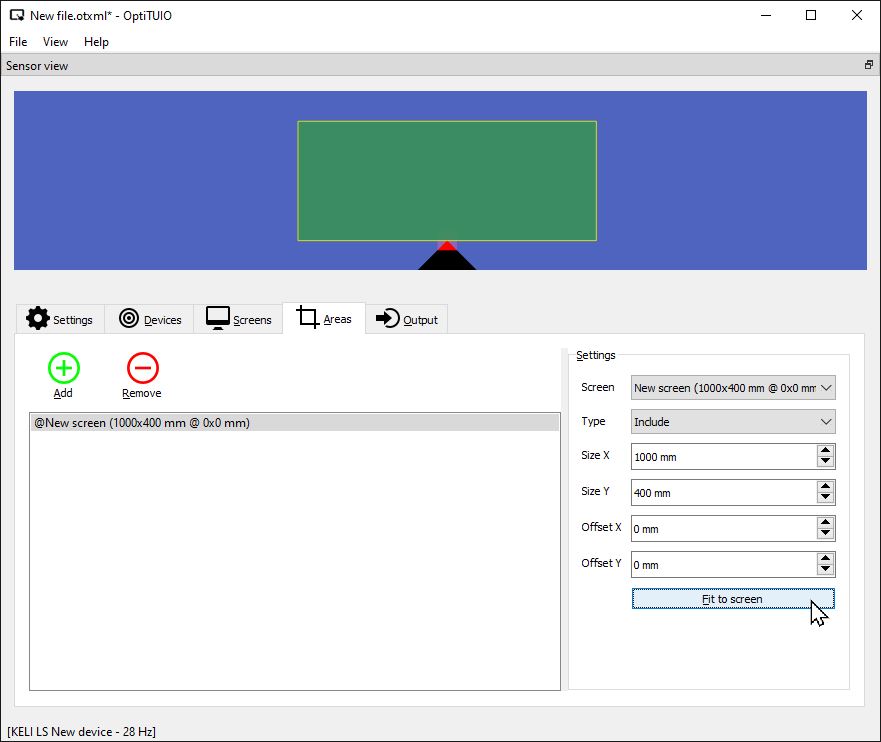

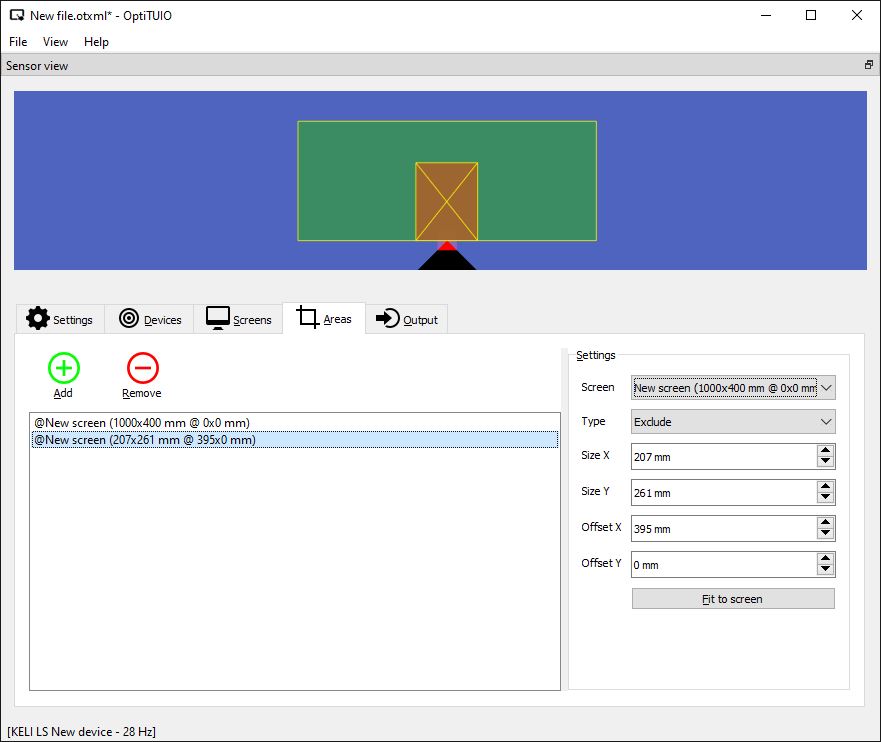

Setup Areas #

For a standard/normal setup you don’t have to do anything here.

In the Areas tab, you can create including and excluding areas. You simply click the button Fit to screen. If you have any areas like doors or other objects in the screen which should not create touchpoints then you can create excluding areas over that specific areas.

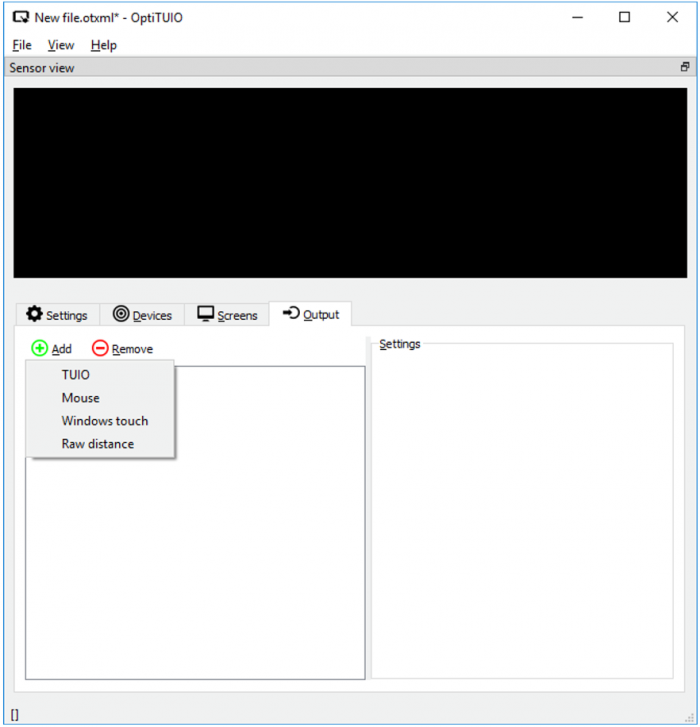

Setup the output #

In the Output tab, you can set up your desired output. OptiTUIO supports TUIO, Windows Touch and Mouse control.

Select your desired output

- TUIO – This will setup an TUIO output which then will directly send TUIO informations to the specified address and port.

- Mouse – This will simply control the computer mouse

- Windows touch – With this output you can simply control Windows touch

- Raw distance – This is a special output which sends RAW distance values to a specific OSC address

TUIO output #

TUIO is a network protocol designed for transmitting MultiTouch input data. It is the de-facto standard for receiving information from MultiTouch devices. Any application which understands TUIO will be able to communicate directly with this output. Typical applications are Ventuz, Unity, VizRT, UE4, and many other media servers or playout applications.

The following list describes the settings of the TUIO output.

- Name – Here you can assign a name for your output

- Host – The machine where OptiTUIO™ will send the TUIO informations (default: localhost / 127.0.0.1)

- Port – The port on the host machine where OptiTUIO™ will send the TUIO informations (default: 3333)

- Screen – If you have more then one screen then you can define from which screen the TUIO information’s will come (default: All)

Mouse output #

The mouse is the primary input device used to interact with objects in Windows, Linux, and macOS. This output will simply control your mouse pointer. There are two different control options with the windows mouse.

The following list describes the settings of the Mouse output.

- Name – Here you can assign a name for your output

- Offset X – Here you can offset your mouse pointer in X direction.

- Offset Y – Here you can offset your mouse pointer in Y direction.

- Size X – This value is set automatically if you start OptiTUIO™. It is the width in pixel of the screens you have connected to your computer. You can change this values if you just want to control one screen.

- Size Y – This value is set automatically if you start OptiTUIO™. It is the height in pixel of the screen you have connected to your computer.

- Screen – If you have more then one screen then you can define from which screen the Mouse information’s will come (default: All)

- Mode – Simple and Two click.

- The simple mode uses the first touch point and moves the mouse directly to that position and executes a left click.

- The two click mode uses two hands. The first touch point or the first hand lets you move the mouse pointer without any click action. If you hold your second finger to left side of your first finger then you can create a left click. Or a right click if you touch with your second hand to the right side of your first hand.

| The mouse just can be controlled with one touchpoint. Or in the two-click mode with a maximum of two touchpoints. There is no way to control two mouse pointers with one OS. |

Windows touch output #

New hardware and API elements in the Windows 7 operating system provide applications the ability to receive input from multiple contacts. This gives such applications the ability to detect and respond to multiple simultaneous touch points on the application’s visible surface. This output of OptiTUIO™simply gives you the ability to control your computer via Windows touch. Please find more information’s on the Windows website: About the multi touch SDK

docs.microsoft.com/en-us/windows/win32/wintouch/about-the-multi-touch-sdk(opens in a new tab)

The following list describes the settings of the Windows touch output

- Name – Here you can assign a name for your output

- Offset X – Here you can offset your mouse pointer in X direction.

- Offset Y – Here you can offset your mouse pointer in Y direction.

- Size X – This value is set automatically if you start OptiTUIO™. It is the width in pixel of the screens you have connected to your computer. You can change this values if you jaust want to control one screen.

- Size Y – This value is set automatically if you start OptiTUIO™. It is the height in pixel of the screen you have connected to your computer.

- Pressure – The Windows touch API has a value called “pressure”. Some touch screens can measure the pressure of a touch point. OptiTUIO cannot measure this value! This value is if a specific application needs a specific pressure value. Then you setup this value here.

- Radius – This is also a API specific value. This is the radius of a circle when OptiTUIO registered it as a touch point.

- Screen – If you have more then one screen then you can define from which screen the Windows touch information’s will come (default: All)

RAW distance #

This is a special output that is used to send raw data of the sensor to a specific OSC address.

The following list describes the settings of the RAW data output

- Name – Here you can assign a name for your output

- Host – The machine where OptiTUIO™ will send the RAW data information’s (default: localhost / 127.0.0.1)

- Port – The port on the host machine where OptiTUIO™ will send the RAW data information’s (default: 7000)

- Address – The OSC address where OptiTUIO™ will send the information’s.

Saving your configuration #

When you are finished with the calibration and you are satisfied go to the Menus -> File -> Save as.

Save the .otxml file at a place where you can find it later. This file can also be opened by a text editor to change values manually.

Run the server application #

After you successfully calibrate your sensor you can close OptiTUIO.calibration.exe and start the OptiTUIO.Server.exe!

The server application will ask you which config file the server should start. Choose your .otxml calibration file and the server will start tracking directly.

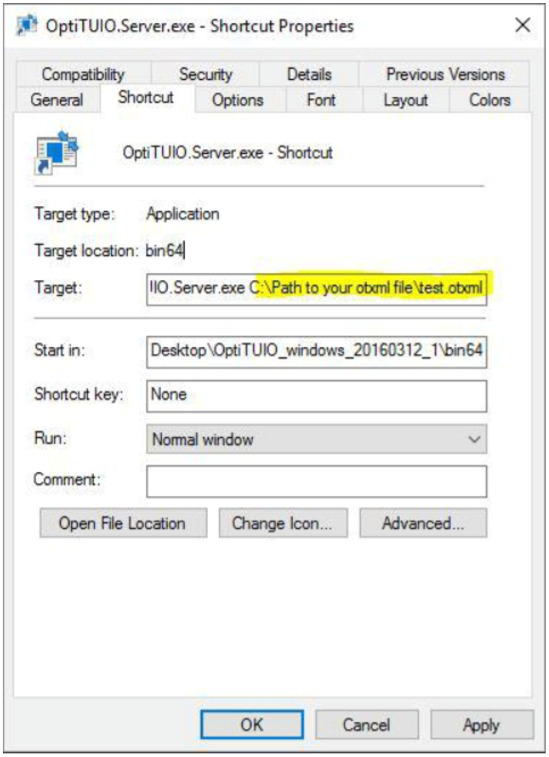

Autostart the server #

If you want that OptiTUIO™ always starts automatically when the system is starting, then follow the description below:

- Create a shortcut of the OptiTUIO.Server.exe somewhere on your machine.

- Open the Properties file dialogue (Right click to the shortcut and click Properties on the bottom of the dialogue menu) of the shortcut and paste the path to your configuration file *.otxml at the end of the Target path. (See picture below)

- Now you can put this shortcut to the autostart folder in Windows.

- The autostart folder you can find here:

C:\ProgramData\Microsoft\Windows\Start Menu\Programs\StartUp

- The autostart folder you can find here:

Licensing #

Device / offline license #

The Device or Offline license is the commercial non-free license. This license is bound to a sensor’s serial number. We also can create a license that is licensed for more than one sensor in one license file.

Demo / online license #

The demo license is for testing purposes only. We activate this license for a maximum of 24 hours. The demo license is just working if your machine has an internet connection.

FAQ #

OptiTUIO is not starting #

Make sure that you have the latest Visual C++ runtime installed. You can find the installer in the OptiTUIO folders. The filename is vcredist_x64.exe

OptiTUIO is not starting the user interface #

Delete the license.otlic file in the C:\Users\yourusername\AppData\Roaming\OptiTUIO folder and start OptiTUIO again. After that install the license again.

Make sure that you run the latest version of OptiTUIO.

File location for the installed license file #

OptiTUIO stores the installed license file in the following folder %APPDATA%\OptiTUIO

Please contact us via email: optituio@interactive-asia.com

OT-500 Bundle #

The OT-500 bundle uses a USB sensor. This means you are limited to the distance of the USB cable. With certain high-end USB cables, you can realize connections of 3 to 5 meters between the sensor and the computer which runs OptiTUIO™.

The OT-500 Bundle is coming with an LDROBOT LD06 sensor. This sensor uses a UART board which will have a unique serial number and this board will also supply the sensor with power from the USB port.

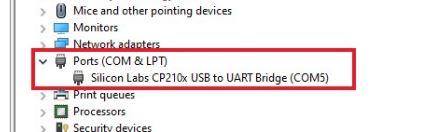

If you have connected the OT-500 to your computer then OptiTUIO will recognize the serial number of the UART board in the device’s settings. (see image below)

If your sensor is not recognized make sure you installed the correct driver for the UART board here:

USB Driver for LDROBOT LD06

Under connection, choose the serial number of the sensor in the dropdown menu, then you are able to start the sensor.